- The Group

- Project support

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

- The Group

- Project support

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

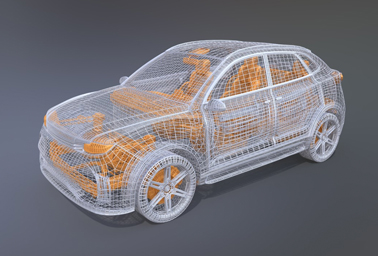

Plastic prototype injection

Thanks to our subsidiary Plastmold, we are also specialized in plastic prototype injection. Established in Châlon-sur-Saône for several years, our company Plastmold is complementary to MDP for prototype injection. With a growing industrial know-how, our group will meet all your requirements in terms of aluminum mold design. MDP Team : your good material prototype from A to Z.

Plastic prototype injection, bi-injection and prototype overmolding

Do you have a plastic prototype to produce before launching a large-scale industrial production? Plastic prototype injection is THE quickest solution to set up. MDP makes your aluminum mold in DAMPIERRE and then entrusts the plastic injection to Plasmold, a subsidiary of the group.

Plastic prototype injection: what does it mean?

In plastic injection, we can start with 100 pieces up to nearly 1 million pieces. Small and medium series prototype injection allows single and multi-cavity injection and overmolding, overmolding of inserts… And the injection of structural parts, appearance parts or transparent parts.

Our know-how is being exported year after year and is progressively expanding in Europe. The quality of our aluminum molds is recognized in this rather restricted sector of plastic injection and “good material” prototype.

Our workshop carries out the desired finishing: painting, surface treatment…

Plastic prototype injection on the one hand and assembly / welding on the other hand

In order to offer you a fully integrated solution, we have decided to create a large group in France and in Europe: MDP Team.

The association of our know-how in the design of aluminum molds and plastic injection allows us to go further by proposing assembly techniques for finished and semi-finished plastic and metal-plastic components. We can also offer automatic assembly with camera control, packaging of your parts or manual assembly.

Three welding techniques are available for the realization of your prototypes:

Vibration or ultrasound

and mirror welding

What is a “good material” prototype?

MDP has become a specialist in good material prototypes thanks to its expertise in aluminum and steel molds. The MDP TEAM group is your development center for the industrialization of your plastic and metal-plastic parts as well as for the assembly of your finished and semi-finished products. The good material prototype is realized in a short time thanks to our technological excellence. The aluminum mold used for the plastic injection of the prototype is then machined and assembled to allow its mechanical validation. The good material prototype is a prototype with real mechanical properties, a controlled design and a good quality finished product.

OUR CERTIFICATIONS

& LABELS >

Copyright © MDP TEAM