- The Group

- Project support

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

- The Group

- Project support

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

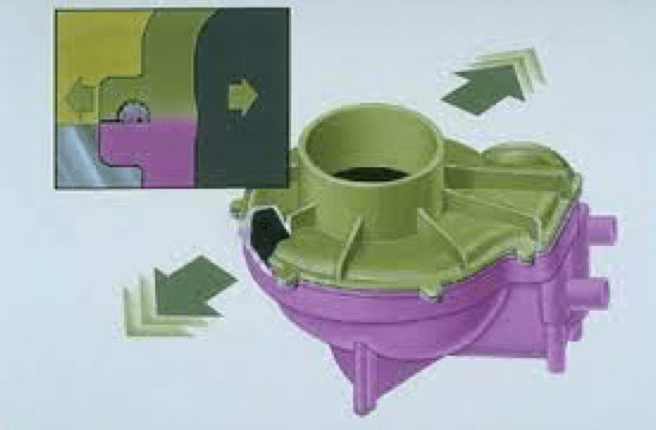

Plastic vibration welding and plastic ultrasonic welding

MDP – Moule Design Prototype realizes the welding of your prototype or your parts in small / medium series. Once the plastic injection has been carried out by our subsidiary Plastmold, we can weld your plastic parts using our vibration plastic welding and ultrasonic plastic welding machines.

Plastic vibration welding or plastic ultrasonic welding ?

MDP Team has both ultrasonic and vibration welding machines. These two plastic welding techniques offer unprecedented precision and reliability to your assembly process. With these two types of welding, our team can produce your good prototype in only a few weeks.

Ultrasonic plastic welding, a technique that is not new !

Since the 1950s, ultrasonic energy has been used to join thermoplastics.

In ultrasonic plastic welding, vibrations pass through the part and create friction between the parts. The friction creates heat and then melts the interface between the parts to form the weld.

Like its big brother, vibration plastic welding, ultrasonic plastic welding offers reliable welds for even the most complex and demanding applications.

Ultrasonic plastic welding is fast and efficient. It provides a strong, clean and airtight weld. Thus, MDP guarantees a high production yield without compromising the quality of your good material prototype.

Plastic Vibration Welding

Plastic vibration welding is a highly reliable process that welds parts known to be strong, accurate and provide years of trouble-free service.

What is a “good material” prototype ?

MDP has become a specialist in good material prototypes thanks to its expertise in aluminum molds. The MDP TEAM group is your development center for the industrialization of your plastic and metal-plastic parts as well as for the assembly of your finished and semi-finished products. The good material prototype is made from an aluminum mold and in a very short time thanks to our technological excellence. The aluminum mold used for the plastic injection of the prototype is then machined and assembled to allow its mechanical validation. The good material prototype is a prototype with the same qualities as an injected part but with a short production time and lower investments.

OUR CERTIFICATIONS

& LABELS >

Copyright © MDP TEAM