- The Group

- Project support

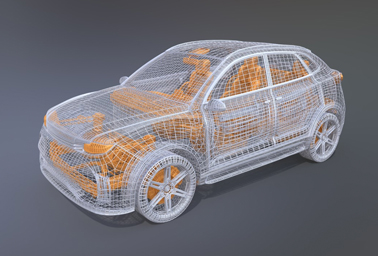

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

- The Group

- Project support

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

A modern machine park and high-tech molds for all your projects.

From the manufacture of your mold to the industrialization of your products in small and medium series

1# Design and recovery of your 3D files

Thanks to our design office composed of 10 people, we can respond to the most complex projects in all sectors of activity. Our technical team also has a real technological arsenal to carry out the design of your molds, their machining and the injection of your plastics for the manufacture of your prototypes, small and medium series.

2 # Co-développement : Design, Analyse, Conduite projet en collaboration avec nos clients

Whether you are a start-up, an individual or an industrialist, an expert or a beginner, MDP Team has been accompanying all its clients for more than 20 years in all phases of the project. With a complete team of engineers, technicians and experts in 3D solutions, we advise and guide our customers in order to obtain an optimized final result.

3 # MDP Team : your machined mold specialist

The second step in our production process is the design of an aluminum mold for plastic injection. Our organization, which is based on the provision of all the necessary skills, allows us to guarantee you a high level of responsiveness, which is essential upstream of your projects. We have a high-speed machining center with 8 CN 4 and 5 high-capacity axes (3200x1200x750) palletized with a deep-hole drilling machine. Machined Materials: Various plastics, Transparent materials, Aluminum of all shades, Various metals - SteelComposites - Foams - ...

Short deadlines

Prototype mold good material: between 2 and 6 weeks depending on the size and complexity of the mold. Small series mold: between 4 and 8 weeks depending on size and complexity.

4 # Plastic injection: the original material prototype

The third step of our production process is plastic injection, in prototypes, small and medium series. Thanks to our Lean Manufacturing organization and our varied press park, we are able to produce plastic injections in series of 100 to 100 000 parts.

Our expertise

Plastic injection, bi-injection and overmolding of technical and appearance parts. Other types of injections are possible: Injection and overmolding mono and multi-cavity. Injection of structural parts. Injection of appearance parts. Injection of transparent parts. Overmolding of inserts.

5 # Welding: assembly of semi-finished and finished components

Integrate the capabilities of the machines as for the others.

Our expertise

Assembly of finished and semi-finished plastic and metal components. Automatic assembly with camera control, packaging, labeling,... Manual assembly. Vibration welding. Ultrasonic welding. Mirror welding. Making of assembly, welding and control fixtures.

OUR CERTIFICATIONS

& LABELS >

Copyright © MDP TEAM