- The Group

- Project support

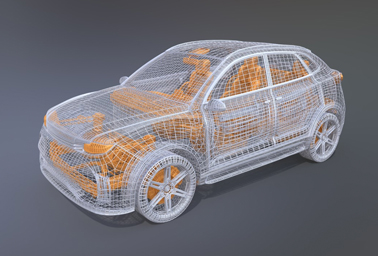

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

- The Group

- Project support

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

Machining of small series parts

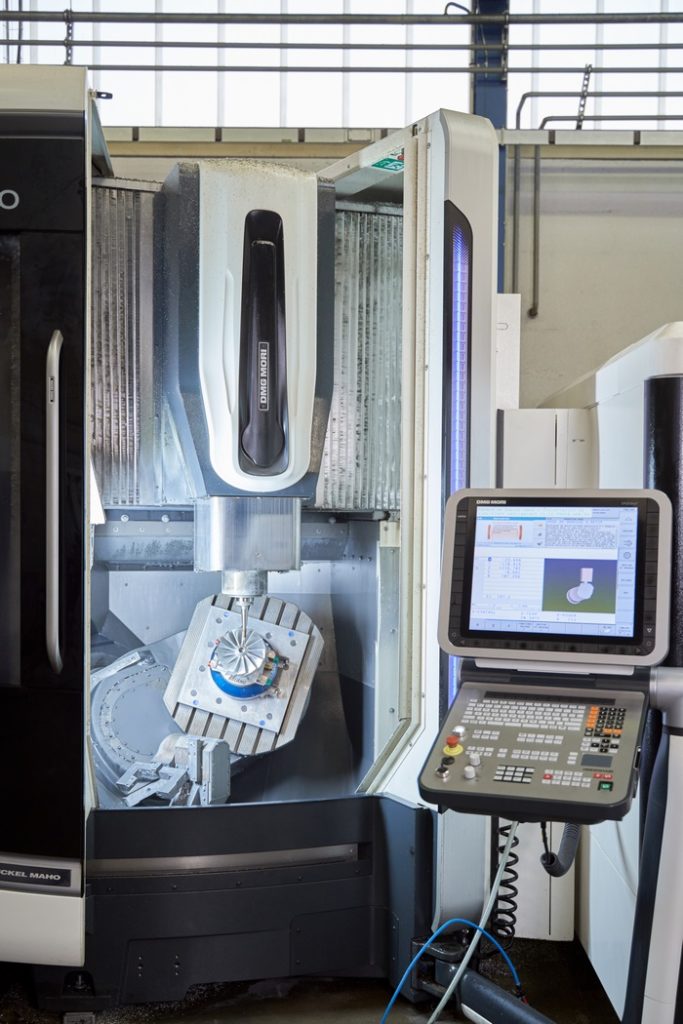

At MDP Team, we have developed unmatched expertise in the machining of parts in small series, whether aluminum or steel. Thanks to our state-of-the-art equipment and highly qualified team, we are able to meet the strictest requirements of various industrial sectors, The European Commission has already published a report on this subject.

Advanced Production Capacity

We have recent and efficient machining centers, including 3-axis and 5-axis machines. These equipment allow us to carry out complex operations with great precision, thus guaranteeing the high quality of each piece produced.

3-Axis Machining: Our 3-axis machines are ideal for parts requiring simple to moderate operations. They offer excellent accuracy and speed of execution, which is crucial for small series where production time must be optimized.

5-Axis Machining: For more complex parts, our 5-axis machining centers offer increased flexibility and precision. These machines allow machining from different angles, thus reducing the number of manipulations and ensuring a better quality of surface and shape.

Applications in the aeronautics

Aeronautics is an area where precision and reliability are essential. Our small series machining capabilities allow us to meet the specific needs of this sector, such as:

Rapid prototyping: Rapid development of prototypes to test and validate new designs.

Structural Parts: Manufacturing of critical parts requiring high precision and high strength.

Mechanical Components: Production of various mechanical components with strict requirements for quality and performance.

Benefits of our expertise

1. Superior quality: Thanks to our modern machines and technical expertise, we ensure an impeccable manufacturing quality, respecting the strictest tolerances. Each part is controlled at several stages of the production process to ensure that it meets the required specifications.

2. Flexibility and Responsiveness: Our ability to produce small series allows us to respond quickly to the requests of our customers, whether it is prototypes, spare parts or small quantity production. This flexibility is particularly appreciated in the aeronautics sector where deadlines are often critical.

3. Customized Solutions: We work closely with our customers to understand their specific needs and develop custom solutions. Whether it’s cost optimization, performance improvement or the development of new parts, we put our expertise to their service.

4. Continuous Innovation: At MDP Team, we are constantly investing in the training of our staff and in the acquisition of new technologies. This approach allows us to stay at the forefront of precision machining and offer innovative solutions to our customers.

OUR CERTIFICATIONS

& LABELS >

Copyright © MDP TEAM